– OPTIME and OPTIME C1

– OPTIME and OPTIME C1

Schaeffler OPTIME receives the “Red Dot Award“ 2021

High-scale monitoring at the lowest cost

OPTIME – Plug. Play. Predict.

Condition monitoring can be expensive. Which is why up to 95% of all machines inside factories are only sporadically monitored, or often not at all. This can lead to unplanned breakdowns and downtime.

OPTIME from Schaeffler allows for comprehensive condition monitoring that is both easy and affordable. Thanks to its simple plug & play installation, OPTIME allows you to start monitoring hundreds of rotating machines in just a few hours.

With the ability to work on almost all machines, OPTIME can detect potential damage, imbalances or misalignments – even weeks in advance! This enables you to easily and conveniently plan your long-term maintenance, manpower or spare-parts requirements

Introducing the world’s first intelligent smart lubricator: OPTIME C1

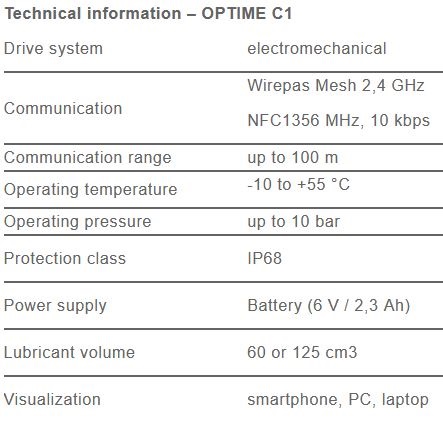

The innovative lubrication monitoring solution consists of the smart OPTIME C1 lubricator, a C1 cartridge, a gateway, and digital service.

An app visualizes the data on a mobile device. (e.g. smartphone). The fill level of the lubricant cartridge and faults, such as line blockages, are displayed here.

The relevant data is transmitted directly from the OPTIME C1 to the Schaeffler cloud. The data can be conveniently accessed at any time and from anywhere. There is no need for control rounds. This saves time. Thanks to its compact design, the OPTIME C1 can be mounted almost anywhere – even in hard-to-reach places. This reduces the risk of accidents enormously.